Creation Willi Geller

Simply BRILLIANT

Inspired by the desire for a life-like copy of nature, the internationally renowned dental technician Willi Geller created a metal-ceramic series in 1988 that caused an absolute sensation: for the first time, perfect, true-to-nature restorations were possible. Founded as a one-man company more than 30 years ago, the dental company has continued to grow and develop steadily. Today, Creation is one of the world's most important manufacturers of discerning ceramic systems as well as of resin and composite teeth with a distinctive character. The ceramic materials and denture teeth are used successfully in more than 70 countries.

The name Creation stands for high-quality and aesthetically refined dental ceramics - whether for anterior and posterior crowns, veneers, inlays, onlays, bridges or implants. Creation ceramic systems are reliable, expressive in their colour effects and brilliant in their results, and the long-term behaviour as well as the firing and dimensional stability of the ceramic materials are also exceptional.

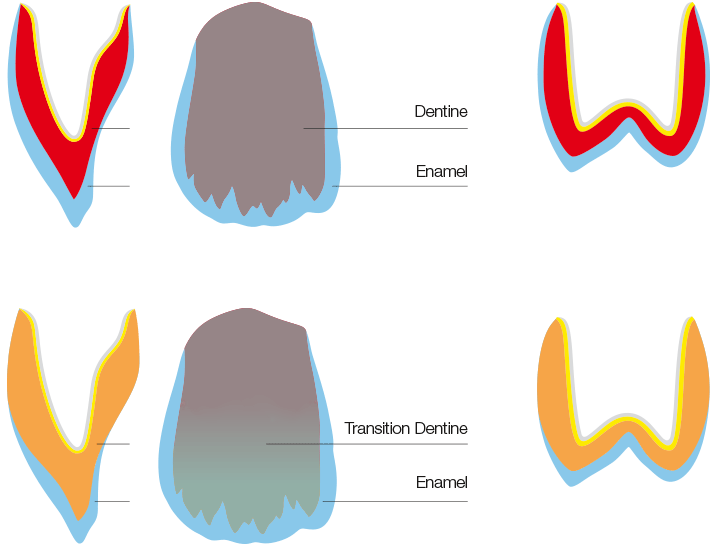

The dentine materials have a high opacity and, same as in nature, must be overlaid with transparent materials in the cervical area.

Exception: the Transition Dentines (TD) from Creation CC can be layered conventionally (not analogue to nature).

The ceramic should always be kept moist during layering. Remoistening is not performed with modelling liquid, but with distilled water. Wet-on-wet layering is commonplace and, because of the modelling liquid, dimensional stability is basically guaranteed even with very wet layering.

Long-term cooling is the slow cooling of objects after firing to a temperature of approx. 500 °C. SC is necessary especially for massive restorations made of zirconium oxide or if there are high differences in the CTE of the alloy and the ceramic. Slow cooling reduces stress within the ceramic during the cooling process and prevents cracks in veneers.

With the Wash Opaquer, the first opaquer firing can already be performed at 950 °C compared to conventional opaquers. After WOP firing, the second opaquer firing is continued as standard. For this reason, the Wash Opaquer is particularly suitable for high-gold alloys and electroplating frameworks with a low solidus point.

Corrections are made with the correction material CM and fired at a lower temperature (compared to the layering material).

Crea Alloy Bond is used for non-precious metal and other highly oxidising alloys. The bond reduces oxide formation and slightly compensates for stresses between the framework and the veneering ceramic.

The veneering framework should be designed such that the layering ceramic can be applied and fired with an even thickness of the layer. The moisture content of the ceramic must be kept as constant as possible during the entire layering process.

The interdental regions of bridges should be separated with a wafer-thin instrument before firing.

The paste opaquer must be applied in thin and even layers. The starting temperature and the heating rate according to the manufacturer's instructions must not be exceeded under any circumstances to allow the organic components to escape completely during drying.

Zirconium is a very poor conductor of heat, therefore large-volume zirconium dioxide restorations must be heated very slowly. The firing parameters for zirconia ceramics are described in the respective processing instructions. Massive, large-volume restorations must be cooled to 500 °C by slow cooling.

ZI-F is a low-fusing feldspar ceramic. The F in ZI-F stands for the high feldspar content.

ZI-CT is a high-fusing feldspar ceramic enriched with leucite crystals.

To improve adhesion, the transparent, fluorescent Frame Shade Neutral (FS-NT ZI-CT or FS-NT ZI-F) is applied to the clean framework and fired.

All commercially available investment materials for press ceramics can be used with Creation LS Press. The processing instructions of the investment material manufacturer must be observed.

Pressing with two press blanks is not approved. Depending on the size, the maximum wax weight of 0.8 g allows two to three restorations to be pressed. If the amount of wax is exceeded, the use of a further investment ring is recommended.

The fabrication of bridges from Creation LS Press is not recommended. According to ISO standard 6872, the pressed ceramic meets the requirements of three-pontic bridges up to and including the second premolar. However, this would require connector dimensions between the bridge abutments and the pontic which are not feasible in most cases.

Veneering of zirconium dioxide with Creation LS is not recommended, as the ceramic has not been tested for zirconium dioxide as standard. Creation ZI-CT is a ceramic specifically developed for zirconium dioxide with a wider range of shades, and is more suitable for veneering zirconium dioxide.

Creation LS was tested and assessed as being suitable for veneering IPS e.max (Ivoclar Vivadent), Concept Press (Ceramay), 88Press and Rosetta (both Hass) as well as GC Initial LiSi Press.

Make up Neo and In Nova Neo are compatible with Creation LS and Creation LS Press. The stains can be added in small quantities to the layering materials. In Nova Neo can be used for wash firing. Make up Neo stains are suitable for colouring monolithic crowns, inlays and onlays.

Due to the range of indications (single-tooth restorations), gingiva materials are not necessary.

For fixation in the mouth, either adhesive composite cements (e.g. G-CEM LinkForce) or self-adhesive composite cements (e.g. G-CEM LinkAce) are recommended.

Prior to fixation, etch the bonding surfaces of the restoration with hydrofluoric acid gel and clean thoroughly afterwards. Before insertion into the patient's mouth, treat the composite surfaces with a silane bonding agent (e.g. CERAMIC PRIMER II or G-Multi PRIMER).

CreaColor can be combined with all press and layering ceramics. In Nova Neo should only be used for tinting layering materials and for internal effects during layering, but not for surface colouring.

The chroma or shade of a restoration can, for example, be intensified or adjusted with the Make up Neo A, B, C or D shades.

Zirconium dioxide can be tinted with Make up Neo and with In Nova Neo. Ideally, the highly adhesive Frame Shade NT (FS-NT ZI-CT or FS-NT ZI-F) is fired as a first step, sandblasted and then coloured in a second step with Make up Neo or In Nova Neo. For this purpose, please read the processing instructions for Creation ZI-CT and ZI-F.